IoT and the circular economy

IoT is a key enabler of the circular economy, helping you source, produce, service and reuse things more sustainably and in an economically viable way.

The Internet of Things (IoT) has an important role to play in the circular economy, by helping your business keep products in use in a way that makes money plus enhances the customer experience.

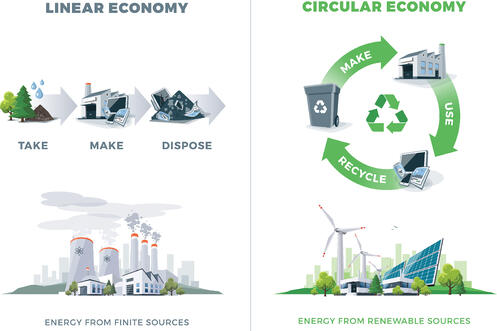

Among the many challenges today, one of the most impactful is climate change. Every country is affected and has a part to play in changing their ways to save the planet. Thus, discussions around a circular economy have increased, as the current approach of mass producing and throwing away is not sustainable.

A circular economy, as described by the Ellen MacArthur Foundation, involves designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. The idea is to stop the “take-make-waste” linear economic model.

Take white goods (fridges, freezers, washing machines); a huge amount of energy and materials go into making these machines. If you look at a refrigerator with components that are not easily fixable or replaceable, when one part fails the whole fridge is often thrown away in order to buy a new one.

If that part could be repaired, the owner need not go through the hassle and expense of buying a new one and getting it delivered and installed. They would also remain with the same manufacturer, rather than possibly picking another. The fridge is designed and manufactured for continued usage – this is the circular economy.

How can the Internet of Things help?

The manufacturing sector has for some time now been using sensors and devices as part of IoT projects in order to improve efficiencies, detect and prevent issues before they occur and maintain products remotely. Remote monitoring is becoming the norm, with manufacturers now seeking to extend this to improve the customer experience to build brand loyalty.

One example might be a company selling manufacturing equipment. It includes sensors to detect pressure changes, fluid levels and more, so that they can provide a better customer experience – supporting customers and informing them before a problem may occur. They may be able to see that they are not using it in the right way, or need to clean it more regularly etc., extending the equipment’s lifespan.

As more and more companies commit to the green economy, it is inevitable that these use cases will expand from the manufacturing marketplace into the retail space for consumer goods. IoT platforms will collect the data from sensors on all types of products, which will help companies use analytics to understand:

- How their products are being designed and manufactured in line with more sustainable goals, including using more sustainable and reusable materials as part of the build process.

- Tracking the provenance of the materials ensures their sustainable credentials, as well as reducing the impact of counterfeit parts

- Which sensors provide the best data and where they should be used to design products with reuse and repair in mind

- How to reduce waste by checking water wastage and other materials used in the process

- Tracking any failures once they are in use with customers and assessing and preventing issues before they happen. A text to a customer can alert them to an issue which may require a part to be sent or an engineer to fix

- Looking further ahead, the use of virtual reality video goggles to overlay a virtual video onto the product, or at minimum having an expert performing problem determination remotely using central data and analytics and advice to a local, more generic engineer

- Tracking a product’s end of life and recalling it to reuse as appropriate.

On the way to a circular economy

As Philips CEO and Chairman, Frans van Houten, says: “For a sustainable world, the transition from a linear to a circular economy is essential…”

Of course, it will likely take time and be an iterative process for companies to shift to this new way of processing and manufacturing. But many such pioneers are already on that path of change.

- IKEA announced its scheme to re-sell furniture after use.

- John Lewis has started a buy-back scheme on clothes bought. As people are able to regain the costs of products bought, the value of such items goes up, as it is not money thrown away.

- Unilever has committed to an “absolute plastics reduction” across its portfolio, starting with design which reduces the amount of plastic used, and then making sure that what it does use increasingly comes from recycled sources.

- Bosch has the “Papillon Project” where all stages of the production cycle can be designed for reuse. Bosch has opted for a leasing business model, which some consumers may like, but some may prefer to buy outright. Different models will likely evolve and be tested with consumers.

- Stanley Black & Decker is a prime example of leading the way with “IoT for Good” as part of the Stanley Earth initiative. Stanley Black and Decker’s NADI Smart Solar Pump is being used in India, where many farmers needing water to irrigate their crops, rely on electricity or if they are off-grid, they rely on diesel. They also need to travel to the site, to switch the pumps on. “But diesel pumps spit out tons of carbon dioxide,” said Stanley Black and Decker in a video. So, it’s important to replace these inefficient pumps with solar pumps that can be monitored, updated and controlled remotely. The NADI Smart Solar Pump has no dependency on the electricity grid, nor fossil fuels. Farmers don’t even have to use diesel to drive to be on site, as they can switch the pump on and off on their smart phone from their home and see IoT analytics and graphs. These are collecting data from sensors to provide remote monitoring, predictive maintenance and trend analysis. They can schedule on and off times and just use the right amount of water to minimize the impact on the water supply. Water quality sensors also help to detect contaminants in the water being pumped.

The circular economy is gaining traction to provide people with the goods and services they need, whilst minimizing the impact on the planet. The IoT is pivotal in providing the connections in the design and build process. It is instrumental in connecting your home and you to the person who fixes your products, to the manufacturers who can tell you when it needs fixing and to the retailer who sold you the product when it needs updating or replacing.

For those companies pioneering an economical revolution to replace the damaging linear economy, IoT is a key enabler to helping them source, produce, service and reuse things more sustainably and in an economically viable way.