How do you make hyperautomation a success?

Process excellence involves methods & technologies aimed at optimizing the performance (times, costs, quality, etc.) of your company’s core processes.

As hyperautomation becomes one of the top trends for 2022 and beyond, your organization must be prepared to get the most out of automation initiatives.

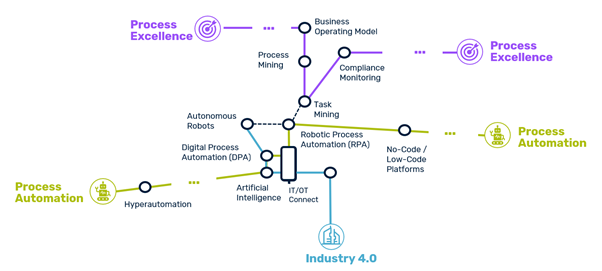

Here, as part of my series on the trend map ebook of Business Transformation & Operational Excellence, I take a closer look at the relationship of process excellence and process automation.

Process excellence is often used synonymously with operational excellence, but it focuses more on the journey than the destination. Process excellence involves the methods and technologies that are aimed at optimizing the performance (in terms of times, costs, quality, etc.) of your company’s core processes. And, in recent years, the trend towards automating these processes and tasks has intensified significantly.

These technologies are quite diverse, and Gartner created the term “hyperautomation” to describe the business-driven approach to automate business and IT processes by the use of multiple technologies.

Automate

Essentially, there are three relevant types of automation technology:

- Workflow automation / Digital process automation (DPA) focuses on more complex end-to-end processes and ensures that all tasks are executed in the correct logical order und by the appropriate employees and roles.

- No-code / low-code platforms are visual software development environments that allow even citizen developers to create (not too complex) business applications.

- Robotic process automation (RPA) refers to software robots which imitate human users, automating the repetitive and routine tasks of office workers by manipulating data and processing transactions within software applications.

Automation is a big trend, but it is too easy to think of achieving business value purely through automation. A patchwork of inconsistent, uncoordinated technologies is a horror scenario that you should avoid at all costs. Automation without prior optimization is like sitting in a Formula 1 car with a 20 HP engine and having only a vague idea of the destination of your journey.

It would be a mistake to give citizen developers powerful tools for automation without understanding the underlying processes, the optimization goals, and the compliance rules to be respected. Automation isn’t a silver bullet. Instead, it makes much more sense to analyze first, then optimize and then automate.

Analyze

Before implementing automation you need a good understanding of both your existing business processes and the new way of working. If you look at the trend map, the monitoring of the real execution of tasks and processes plays a prominent role:

- Process mining analyzes, in an automated way, the as-is execution of end-to-end business processes to identify bottlenecks and to derive optimization measures.

- Task mining is the automated discovery and analysis of user interactions on a desktop (i.e., the tasks being performed by a single employee).

The combination of process mining and task mining makes a lot of sense, as complex process steps can be analyzed and detailed through task mining. The combined results of process mining and task mining provide a perfect basis for identifying weaknesses along the entire process and at different levels of detail.

Optimize

When weak points are analyzed, you need to think about all aspects of optimization before automation: Very often, organizational disruptions (with waiting and idle times) are one of the main reasons for long throughput times of processes. In addition, for almost all companies, the lack of data integration across business functions is a major obstacle to the successful use of automation technologies.

Collective debt

In many companies, the level of process understanding and the integration across organizational units are quite low (Forrester calls this “the tremendous collective debt within organizations”).

Improving visibility of the actual performance of business operations is another basic prerequisite for improvements. Modern companies provide a digital handbook with an accurate model of the way of working to all employees across the organization to ensure that they understand their specific role and responsibilities.

Process excellence requires constant monitoring and analysis to improve and streamline the processes before and after automation. To succeed, you must have a plan to use mining, analysis, and automation technologies together and to use the methods and technologies along a continuous optimization cycle. Many companies use the term “enterprise management system” for this lifecycle – see my previous blog post for more information.

You can download your copy of the ebook with the detailed trend map for business transformation and operational excellence below.

This article originally appeared in OPEX.