Without change management, IoT has no chance

Regardless of where your IoT project fits on the “complexity scale,” you won’t get very far without a thoughtful approach to organizational change.

Change management is particularly important for IoT initiatives because the Internet of Things affects many different areas of the company— if not all of them. The more complex the project, the more departments that need to be involved and the more employees you need to include to ensure long-term success. In short: the complexity of change correlates with the requirements of the projects.

The complexity scale of IoT and change management

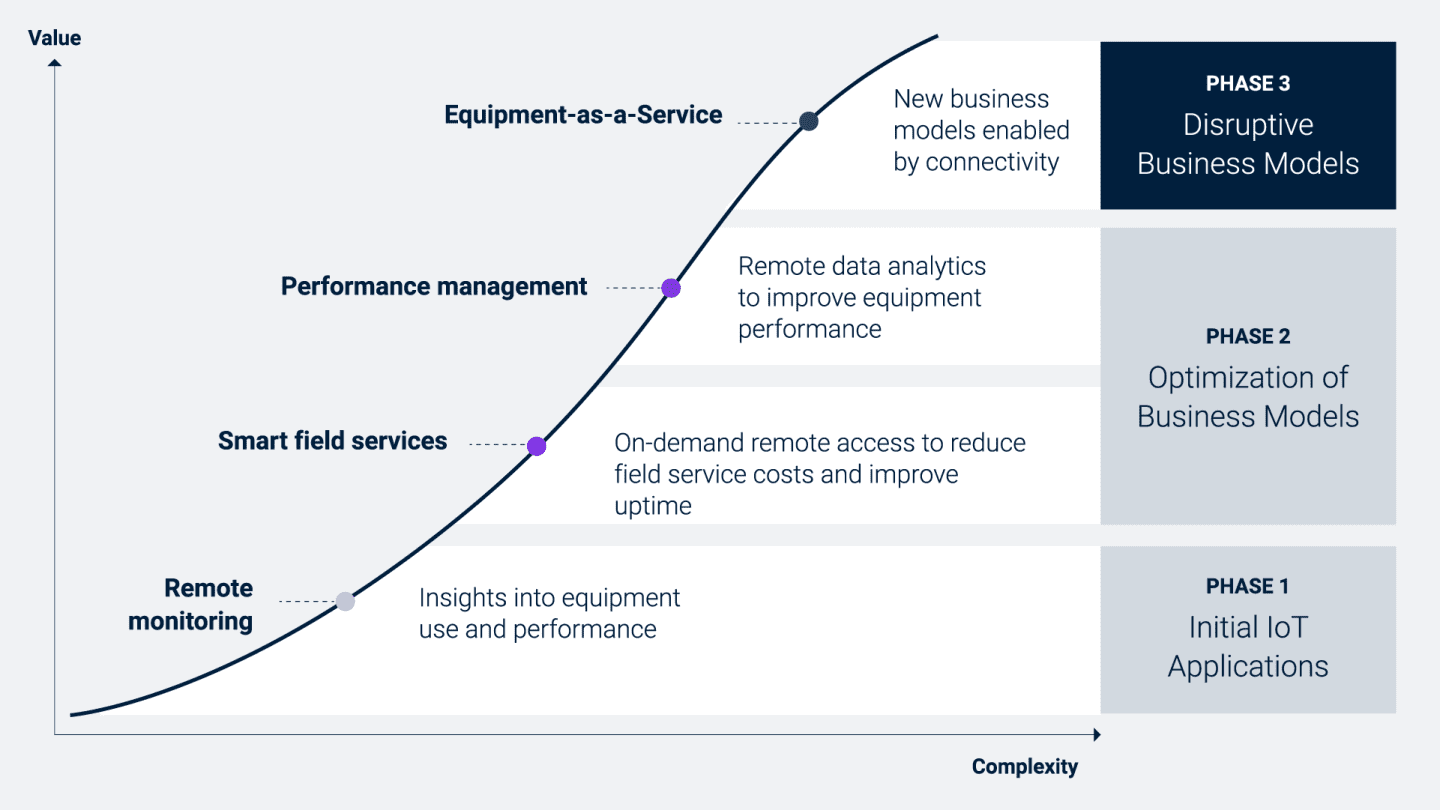

Each IoT project sits somewhere on a so-called “complexity scale.” In an IoT project that involves remote monitoring of devices, the situation is manageable: the main players are the teams from IT, OT and product management, along with champions from upper management. The success of these projects is more straightforward and depends on the plumbing of the connected world.

But at the other end of the complexity scale, IoT projects can lead to disruptive business models such as equipment-as-a-service. They affect the whole company. A machine that was previously sold for several million dollars, for example, would now be sold for several hundred dollars a month based on usage. How is this financed? How is the commission for sales calculated? You have to tweak contracts and get banks on board. Accounting and controlling must also be taken along … The changes run through the entire company.

Recognizing the importance of change management

You won’t get very far with siloed thinking and without organizational change. Identifying the digital unit as a digital incubator in the company is critical.

It should represent everyone who is affected in any way by the IoT project. Ideally, this digital unit is responsible for all IoT projects in the company in order to exploit all possible synergy effects in terms of know-how and costs.

While it will be a while before your disruptive business models are ready for the market, it gives you the best possible opportunity to optimize a few things in your own shop and pick people up with improvements that can be seen and felt quickly. You can quickly progress along the IoT maturity curve.

If, for example, machines or conveyor belts are connected to the IoT, the employees quickly see the advantages: they can see from a distance how the systems are doing or how the conveyor belts are working. With remote monitoring, you no longer have to go on regular inspection tours. In a second step, analytics can be added to enable predictive maintenance to better plan maintenance. More-advanced analytics then enable performance optimization to improve OEE. As a final step, the costs of machine operations can be better tied to production output.

Change management is required — so don’t ignore it

A digital unit can plan and control all of this together with those affected and develop it in intermediate steps that build on one another from small to large. Click below If you would like to learn more about some of the challenges that must be managed with IoT implementation.