Operational Excellence Key Trends to Look for in 2023

If 2022 taught us anything, it’s that making predictions for the upcoming year can be nearly impossible. Operational excellence is a high priority for most companies so with help from Software AG’s Caspar Jans, let’s explore some topics and trends that may play an important role in 2023.

Last year was really challenging and events unfolded differently than expected. Economic uncertainty forced many companies to shore up their business transformation initiatives. Since we know operational excellence is a high priority for most companies, what are the topics and trends that will play an important role in 2023?

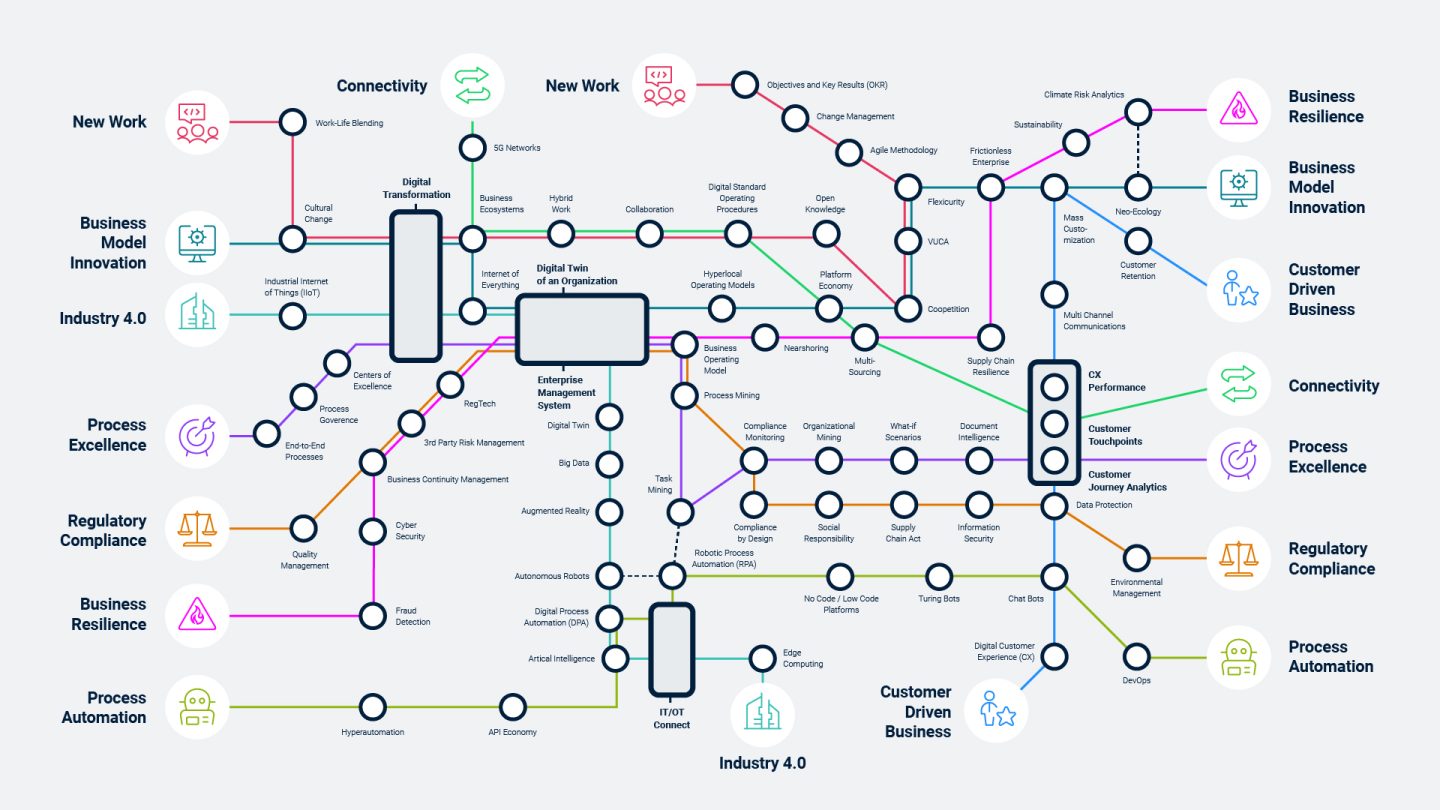

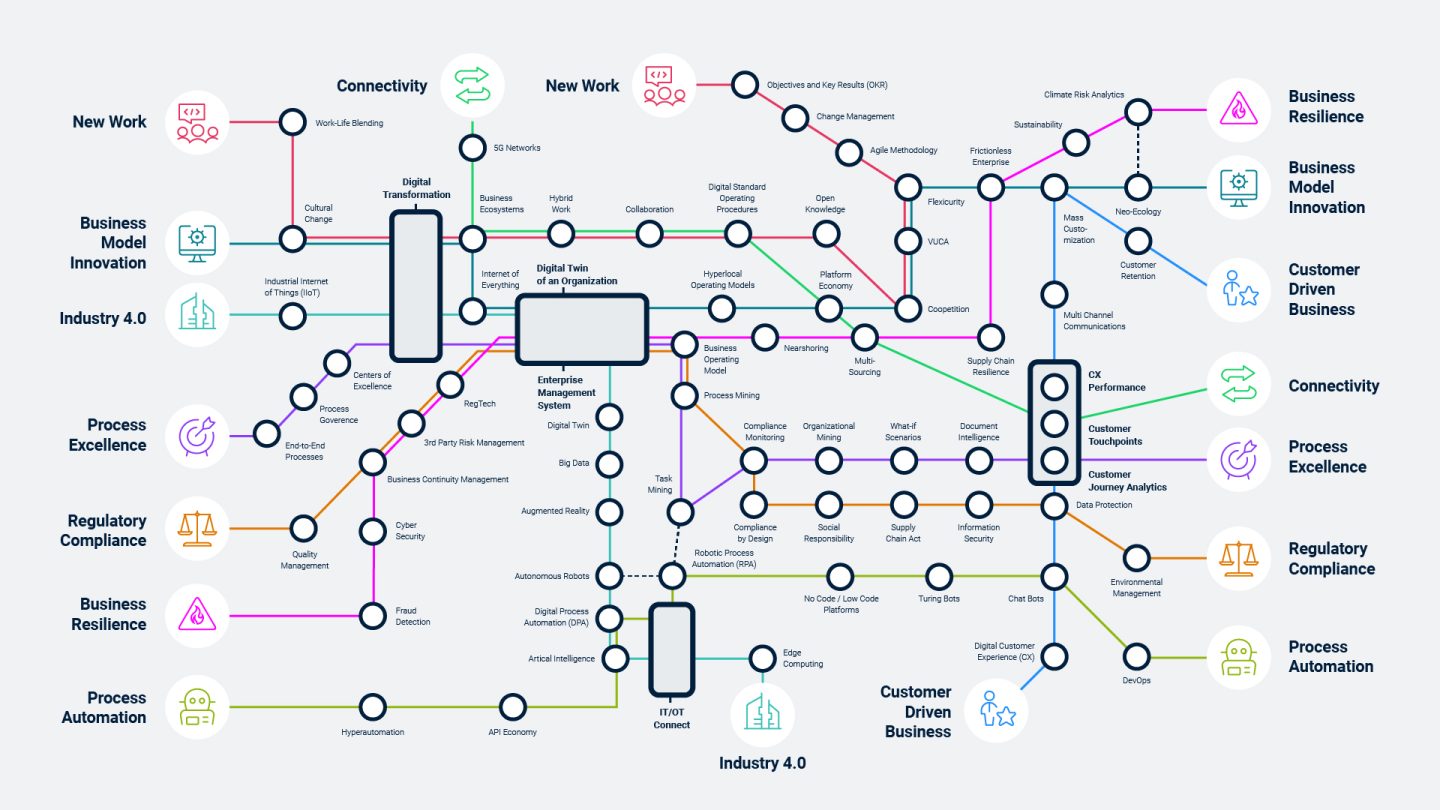

Operational excellence has many objectives and subtopics so a trend map can help bring transparency to this landscape. Like a subway map, the solid-colored lines represent the primary navigation elements of operational excellence. We call those “core topics.” Important trends related to these different core topics are represented on the map as “stops.” Core topics meet and influence each other at major intersections.

Let’s take a closer look at some of the most important operational excellence trends represented on the trend map, below.

Shifting focus to resiliency and effectiveness

Against the backdrop of geopolitical risks, and high inflation rates and energy prices, economic uncertainty will be with us for some time to come. As a result, companies were forced to adapt their supply relationships, ecosystems, and, in some cases, their entire business model. This led to a massive adaptation of the operating model and subsequent business processes. Despite returning to a somewhat normal state, business leaders still view supply chains with uncertainty. By shifting their focus — and budgets — towards making processes resilient, business resiliency has become a major objective of operational excellence.

Resilience is defined as “the ability of an organization to adapt rapidly to changing environments and unforeseen events.” So, companies are preparing for these possible threats such as continued supply chain disruptions, natural disasters, cyber-attacks, and the aftereffects of the COVID-19 pandemic. But it’s also important for these organizations to ensure that business processes are not only resilient but effective — for the business, stakeholders, and customers. This is where we see a large overlap between operational risk management and operational excellence. One example is the ISO 22301 standards for business continuity management systems. This requires transparency of business processes, data, IT systems, and responsibilities to define top priorities and plan B scenarios.

Compliance is universal

Compliance requirements continue to grow regardless of industry. We are currently following these observed sub-trends:

- Compliance requirements increasingly include considerations outside of any one company’s area of responsibility or objectives. For example, as of January 2023, the Germany Supply Chain Act — which will be followed by a European-wide initiative — requires risk analysis to be conducted on entire supply chains regarding compliance with human rights, fair labor practices, and environmental protection requirements.

- More and more companies understand that is it counterproductive to create a dedicated management system for each individual compliance topic (e.g., quality, data security, environmental protection, etc.) since each system is based on the same components (processes, data, IT systems, and more). It is more effective to use an integrated management system that maps the various topics and looks for interdependencies or overlap.

- Compliance and audit management is very often still executed using a multitude of manual activities, but automation is expected to dramatically increase as process monitoring enables the automatic review of compliance rules.

Unstoppable adoption of Process Mining

For large companies in particular, the adoption rate of process mining is already at a high level. But process mining will become a mandatory technology for companies of all sizes to be competitive in any industry. We anticipate process mining technologies will grow beyond current use cases and expand into even more aspects of the business.

On one hand, compliance monitoring can be equally important when used alongside process optimization. On the other hand, the gap between IT and OT (Operational Technology) is lessening due to the optimization of production-related processes. Process mining technologies are supporting cross-company process management by analyzing and optimizing end-to-end supply chains and distribution networks.

Economic impact of sustainability

Sustainability is a concern for all organizations, and that concern starts at the executive and board level and trickles down throughout every department and level at a company. It’s an important economic factor to consider beyond the compliance requirements. Ensuring that all business operations and processes are sustainable impacts all the classic goals for process optimization including time, costs, and quality. It also means new objectives must be addressed such as CO2 emissions, resource consumption, and working conditions. This requires the implementation of appropriate reporting mechanisms. Here, too, there are many standards and frameworks that point the way. Two examples are the ISO 14002 for Environmental Management Standards and ISO 26000 for social responsibility.

Employees as consumers driving process management

From an employee perspective, it’s an obvious challenge to ensure that all employees know the way of working, their tasks, and the relevant policies and standard operating procedures. This challenge is augmented by the discussion of what the future of work will look like in 2023 and beyond. There are many surveys about how employees would like to work in the future with working from home and hybrid work among the top requests. Prior to the pandemic, these were very unconventional ways of working, but now, a strong argument can be made that they are here to stay. These changes will certainly impact operational excellence initiatives in 2023 as organizations look at their processes and how they arm each individual employee with all the information they need for their specific role and daily work.

Additionally, process management will impact how employees access information and make decisions. It is critical that companies understand employees’ perspectives clearly as they act as a consumer of the technologies and tools you implement, and then determine what types of presentation and visualization are needed and suitable to meet the needs of those same employees. Moving forward, we see a shift occurring from classic expert-like representations to checklists, videos, and other media that can be used on-demand. This will establish a smooth lifecycle: from creation and dissemination of information to consumption, feedback, and exchange with employees who act as consumers.

In summary, it’s impossible to forecast exactly how process management will affect operational excellence in 2023. However, we can confidently look at these underlying trends and surmise that they will in some way, shape, or form impact organizations as they look to build and execute successful business models.