Unleashing the potential of supply chain through process management

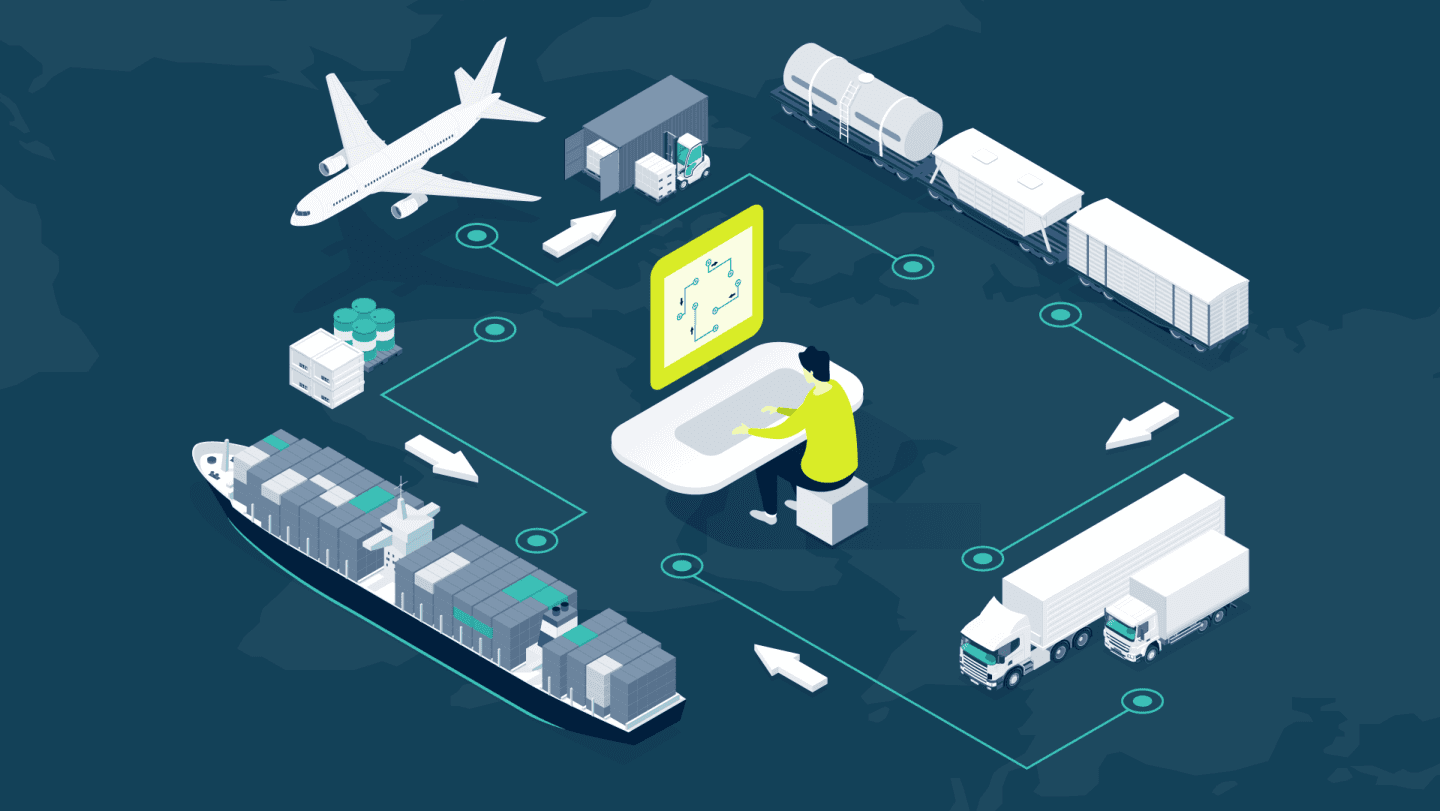

An efficient, transparent, and agile supply chain can remain resilient in the face of disruption with help from end-to-end process management.

In many industries, the resilient design of supply chain and distribution processes has an outstanding impact on customer satisfaction and profit. It is no longer sufficient to consider only the processes within your own company when it comes to optimization and compliance. Process management must encompass the entire supply and distribution networks.

What are the consequences for Process Competence Centers and Operational Excellence initiatives in your organization?

“The supply chain stuff is really tricky.”

Elon Musk

“The real competition is between supply chains, not companies.”

Martin Christopher

Despite the (sometimes painfully experienced) risks of globalization, outsourcing and offshoring continue to be important instruments of business practice. In many industries, resilience and optimization of supply chains and distribution networks have become of paramount importance in recent years. Global events — such as the energy crisis, pandemic, or the invasion of Ukraine — have further strained already shaken global value chains and led to supply shortages for electronic components, computer chips, pharmaceuticals, and food, among others. Over 80% of companies have experienced significant supply chain disruptions in the last two years1.

What are the key challenges companies face in managing their supply chain and distribution networks?

Fluctuations in demand for consumer goods have increased due to more intensive e-commerce and shortened product life cycles. The number of disruptions from different areas (pandemic, political crises, natural disasters, etc.) has reached threatening proportions in recent years. It is necessary to be able to react flexibly to disruptive events in real time.

Accounting for more than 25% of global CO2 emissions, supply chain management is one of the key areas in the fight against climate change. On average, supply chain emissions are 5.5 times higher than a company’s direct emissions.

Although logistics focuses on the physical transportation of goods, it has an increasingly large digital footprint. Cybercriminals have growingly identified the logistics sector as an attractive target. Supply chains are threatened by the major cyber risks like ransomware, phishing, and interception of information along supply chains.

Digitalization of information (such as invoices, export certificates, and waybills) has come a long way. But data integration between partners still needs improvement, as data silos hamper collaboration.

More and more compliance requirements are affecting collaboration between companies. The Supply Chain Act (EU standards will follow), which came into force in Germany on January 1, 2023, aims to ensure that actors along the entire supply chain uphold social and environmental standards. Even though the requirements are graded according to the different stages in the supply chain, companies must have an overview of the suppliers and take action in the event of violations or suspected cases.

Supply chains and distribution networks are currently experiencing a series of technological and conceptual innovations that bring disruptive changes (such as autonomous trucking, robotic warehouses, multispeed supply chains, options on local sourcing). Now, however, it is also imperative to benefit from the methodological experience of process management. Since the 1990s, process management has been able to establish itself as an important cross-sectional unit in companies and to further develop the methodologies and tools into a holistic process lifecycle management (often in the form of an enterprise management system). We are now at a point where a center of process excellence and the process experts must take the next step to maintain their strategic importance and create even greater value for the enterprise. It is necessary to extend the domain of process management to the entire value chains and to apply the set of methods and tools to end-to-end processes as well.

What does that mean in detail?

- Make sure that the management understands the need and the benefits of end-to-end process optimization.

- Engage with your key suppliers and distributors to agree and align on the goals and methods of end-to-end process management.

- Expand the company’s process map to provide an overview of the entire business ecosystem.

- Extend your process management lifecycle to end-to-end processes. This includes defining the operational excellence goals, mapping the to-be processes, implementing a holistic performance management, and measuring and monitoring the as-is processes.

- Establish an agile procedure that combines a continuous design (with focus on resilience and efficiency) witht he process monitoring/analysis insights.

- Establish holistic risk management that integrates all relevant compliance issues that affect end-to-end processes (incl. sustainability, data security, quality, business continuity).

Companies have recognized the need to strengthen supply chains and distribution networks as a strategic differentiator. An efficient, transparent, and agile supply chain increases resilience to disruptions, volatile freight rates, or fluctuations in demand. Process management will only fulfill its strategic mission if processes are understood end-to-end and the tools and experiences of the last 30 years are applied to end-to-end processes.