Go carbon neutral with IoT

Lower carbon emissions with asset condition monitoring and IoT.

One of the more famous quotes in the scientific community is “nothing exists in a vacuum.”

And while I don’t disagree with the statement, I don’t mind misconstruing it to illustrate a point. It can be argued that “carbon” does in effect live in a vacuum. Before I get to the point, a bit of background.

The oil and gas sector is one of the largest emitters of carbon into the atmosphere. In a recent study published by McKinsey, it is estimated that the sector’s fair share of Scope 1 emissions is approximately 9% of the total generated in a year.

As climate change accelerates extreme weather events globally, oil and gas stakeholders are demanding a higher degree of accountability on the measurement, mitigation and reporting of the carbon production process.

But, one of the sector’s operational challenges is that a vast majority of production assets are monitored and controlled with manual gauges. As a result, operating data is either not collected and stored, or collected infrequently during periodic maintenance and service procedures.

Existing in a vacuum

Which brings me back to the point. If operations data is not collected in a timely manner – or at all – then it could be argued that the quantification of carbon emissions exists in a vacuum of information. And if you can’t measure it, it is devilishly hard to manage it.

What if these cases could be measured, managed, analyzed and acted upon to mitigate carbon emissions?

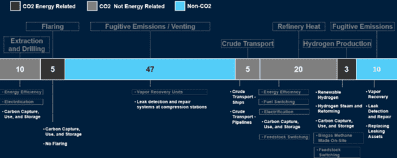

Fortunately, there is a path forward. The McKinsey image (right) captures how the 9% is spread across the production process. And the bottom portion of the graph represents the mitigation practices that you could deploy to reduce your carbon footprint.

There is a common element in the use cases outlined above – they require a foundational technology capability to deliver on their reduction goals – asset condition monitoring (bolded white).

This, combined with an IoT platform, could deliver multiple use cases within the same design environment – that’s critical to scalability across the value chain. And within this platform, the key table-stakes capabilities are the following:

– Connect to any device/sensor

– Analyze the data in real time

– Act on the data

– Support telecom-constrained environments

– Orchestrate workflow to support mitigation efforts

The benefits of asset condition monitoring using IoT, then measuring and managing the data, analyzing it, and making more intelligent decisions based on it using an IoT platform, means you can see where the emissions are coming from. And stop them.

Learn how to mitigate

Recently, in partnership with Infosys, I had the privilege to host a webinar to discuss how IoT technologies could accelerate oil and gas companies carbon mitigation goals. Please feel free to watch and share the webinar, Going Carbon Neutral with IoT, for a more in-depth review of how oil and gas companies can go carbon neutral with IoT technologies.